When to Use Finger Joints and Glue Joints

Finger joints are those in which the ends of the surfaces to be joined together are cut and shaped in a manner that allows them to lock together in a straight or perpendicular way. Glue joints can refer to any shape joined or glued together in mechanical and adhesive ways.

There are several differences between finger joints and glue joints due to the differences in their structures. The applications for which you use finger joints and glue joints also tend to differ and vary considerably.

If you are confused between the two, you can go through the upcoming sections to get a better idea about the meaning, uses, pros & cons of each joint. This will then make it easier for you to choose one for your required purpose.

Finger Joint vs Glue Joint for Woodworking Joints

Finger joints and glue joints broadly tend to differ from each other in the following ways.

- Finger joints are those that require comb-like and complementary cuts on the edges of each wood piece that you want to join. Glue joints are a wider group that includes all possible shapes of joints or even edges simply glued together.

- Finger joints are highly specific, while glue joints are more versatile in their applications.

- You are likely to waste far less wood when it comes to constructing finger joints than several glue joints.

- Finger joints are bound to be more durable than simpler glue joints since they involve both interlocking and gluing.

- Finger joints, due to the time and effort involved in cutting up the precise and complementary shapes, are more expensive as compared to most glue joints. Even then, however, they are quite cost-effective.

- Finger joints and glue joints tend to differ in terms of their applications, and determining which joint to use will depend on the desired strength of the joint and the project itself.

When to Use a Finger Joint

Finger joints have numerous uses and applications, with some overlapping with glue joints too. However, there are some situations in which you should use finger joints over glue joints. Let’s take a look at some of these situations and uses below.

You can increase the strength of your project using a finger joint, although there are some situations in which you will need to exercise caution.

If you need to rely on the joints to withstand irregular pressure or if you need to place your woodwork piece in elevated temperatures.

Finger Joint Pros

Finger Joint Cons

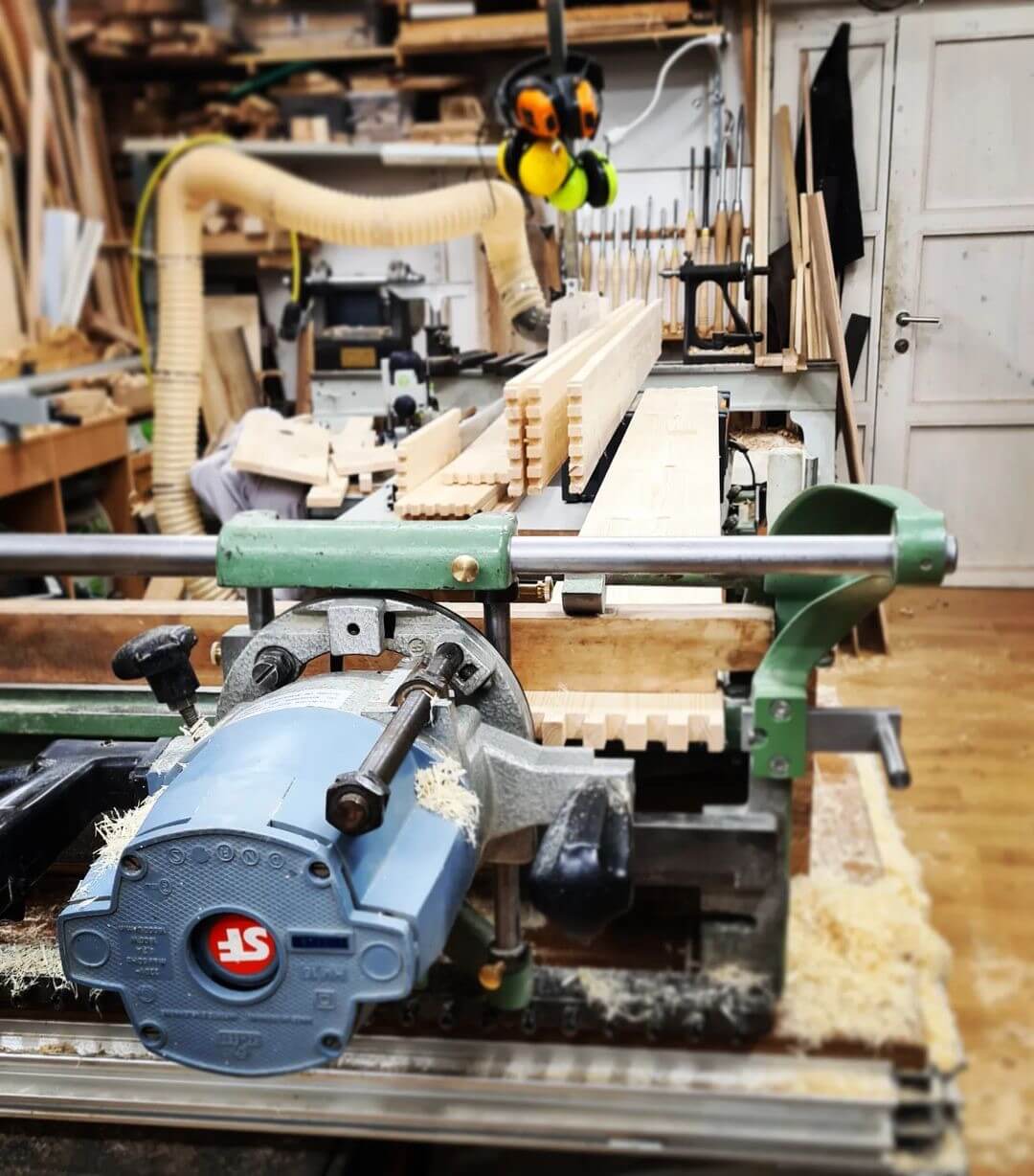

What Tools Do You Need to Make a Finger Joint?

If you wish to make a finger joint between two pieces of wood, it is crucial for you first to gather the relevant tools and materials to ensure the best possible outcome. Here is a list of some tools that you will require.

Make sure you set everything up and test out the design on a small piece of the square before you move on to the larger piece.

When to Use a Glue Joint?

Glue joints have a wide range of applications too. Being aware of these can make it easier to carry these out whenever you want to work on your next project.

Go through the following list of uses and applications so that you know when to use a glue joint.

Due to the adhesive strength and, quite often, the mechanical strength of many of these joints, pressure or stress from a load is more manageable here. This can result in important uses for structural pieces as well as for furniture-based pieces.

Glue Joint Pros

Glue Joint Cons

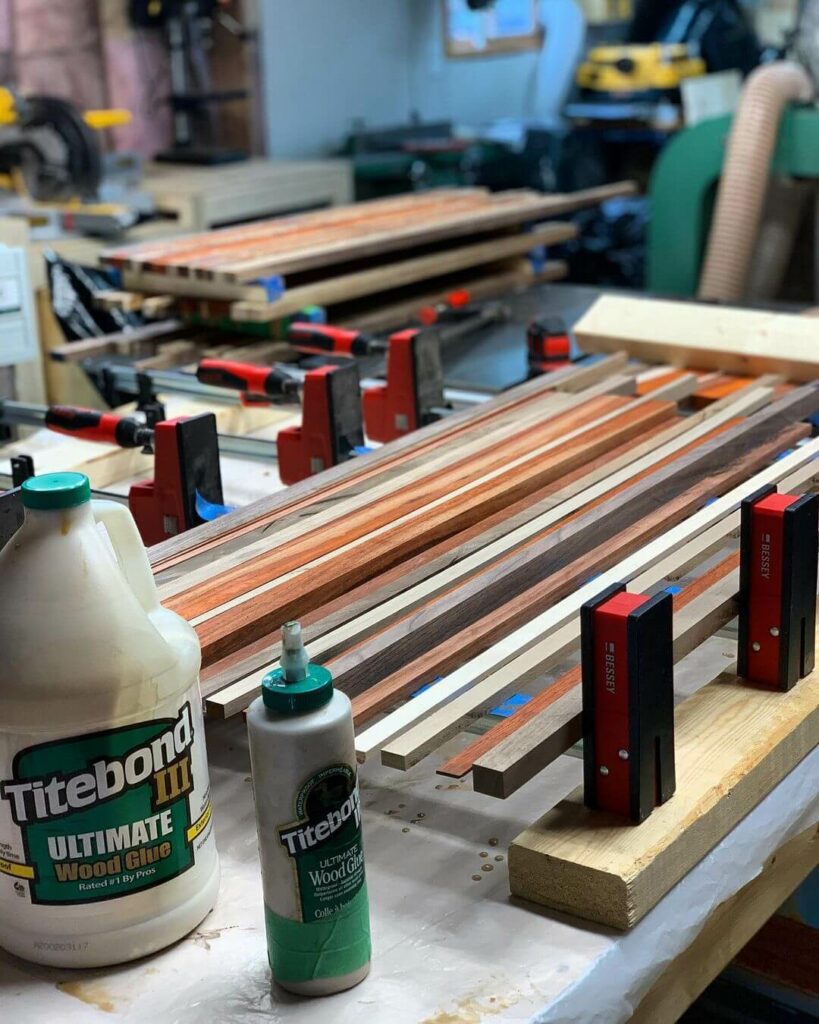

What Do You Need to Make Glue Joints?

If you need to make glue joints, you should gather several materials that can help you carry out the cutting and joining process effectively. Go through the list of these tools and materials below.

After you cut the joints precisely, you should completely wet the surface and joints with glue before you join them together.

Make sure you also maintain cleanliness and smoothness while also altering your machines and saws depending on the kind of joint you want to work with.

What Are the Strongest Types of Joints?

The following types of joints are some of the strongest, offering plenty of convenience and benefits for heavy-duty requirements.

Finger Joints

We have sufficiently covered the meaning, uses advantages, and disadvantages of finger joints. Based on their construction and the combined strength of precise locking and strong adhesion, these joints are some of the strongest options that you can employ for a wide range of projects.

There are also several types of finger joints involved that you can make use of depending on the needs of your project. With precision, you can achieve plenty of stability and strength through these joints.

Dovetail Joints

Dovetail joints are extremely attractive while also having a great deal of strength in terms of their design. These joints include pins and tails of a trapezoid shape that are then joined together using a lock-and-glue mechanism.

The shape of the pins and tails, along with the dual joining system, makes these joints extremely strong and difficult to pull apart. This kind of stability makes them useful for making drawers, boxes, cabinets, and other strength-reliant projects.

Mortise and Tenon Joint

A mortise and tenon joint is used when two wooden or other surfaces need to be joined together. On one of the surfaces, there is a square or rectangular cut or cavity made towards the edge, while the other surface has a protruding piece that can easily fit into this cavity.

The cavity is the mortise, whereas the protruding end is the tenon. These tend to vary in thickness so that the two pieces can lock together in the most efficient manner. You can use these in several kinds of constructions, such as tables, chairs, beds, doors, panels, frames, and others.

What Are the Pros & Cons of Wood Joinery?

The aforementioned joints, along with several other kinds of joints, all fall under the wider category of wood joinery.

There are several pros and cons of this kind of wood joinery that you should account for, some of which are listed below.

Pros

Cons

The Bottom Line

Finger joints and glue joints are similar in many ways, with finger joints usually having a much more streamlined and specific shape and usage.

Both options tend to work well for various structural and aesthetic woodworking projects, so make sure you take your considerations and limitations into account before making a choice.