25 Different Types of Hammers and Their Uses

Did you know there are over 25 different types of hammers? Each type features a unique shape and build that allows it to deliver the right force and drive for specific activities.

In a Nutshell:

Choosing the right hammer is key to efficiency and precision in any task. The claw hammer, a staple in most toolkits, is perfect for driving and pulling nails, while the ball-peen hammer is essential for metalworking tasks. Specialty hammers, such as the brick hammer for masonry and the framing hammer for carpentry, cater to specific jobs. Rubber mallets are ideal for gentle impact, whereas sledgehammers are designed for heavy-duty demolition. Each hammer type is tailored for particular tasks, ensuring the right force and precision, minimizing material damage, and enhancing safety.

Standard Hammers

The first ten hammers on our list are the most common, versatile options that both DIY’ers and professional contractors will use on a daily basis.

You probably already own one or two of these hammers on this lengthy list.

But adding a few more to your tool kit with the different types of saws and hand tools you already own, will only further prepare you well for a broad range of tasks.

1 | Ball-Peen Hammer

The ball-peen (also known as ball “pein” or machinist’s) hammer is popular in the engineering and metalworking industries.

Ball-peen hammers have two heads: one that is flat and one that is round. This adds versatility as you can tackle a greater number of tasks.

Engineers typically use these types of hammers for shaping metal or striking chisels, and are a great all-rounder to have in your tool chest.

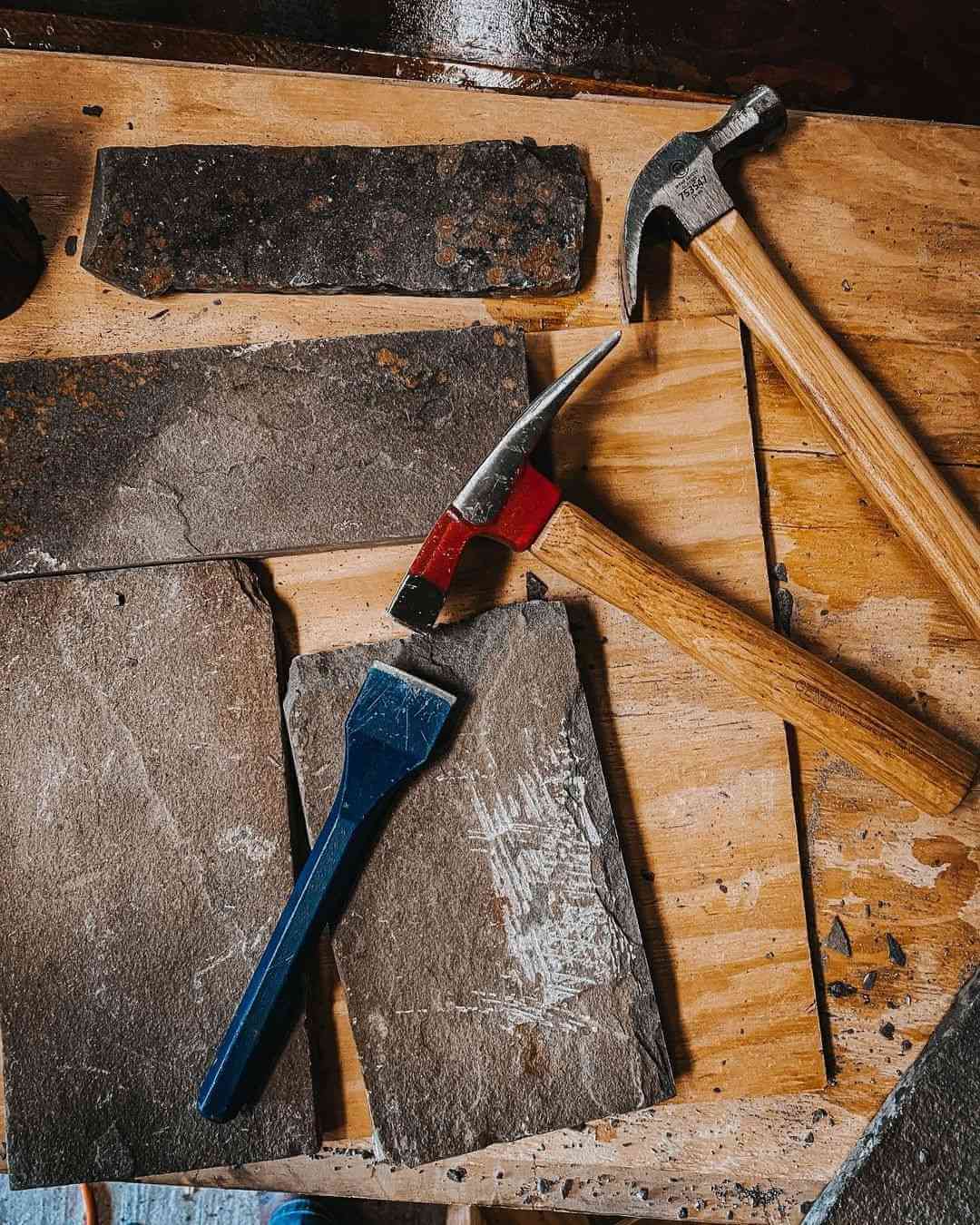

2 | Brick Hammer

Brick (or stonemason’s) hammers have a flat head and a pointed, with a chisel-like claw on their back end.

As its name suggests, a brick hammer can break bricks, concrete, or stones with ease. The chisel end of this hammer is used for scoring, while the blunt end is used for smashing with less precision.

This is why bricklayers often keep brick hammers within reach during masonry projects, and if you’ve got a DIY bricklaying job coming up, a brick hammer is a must-have.

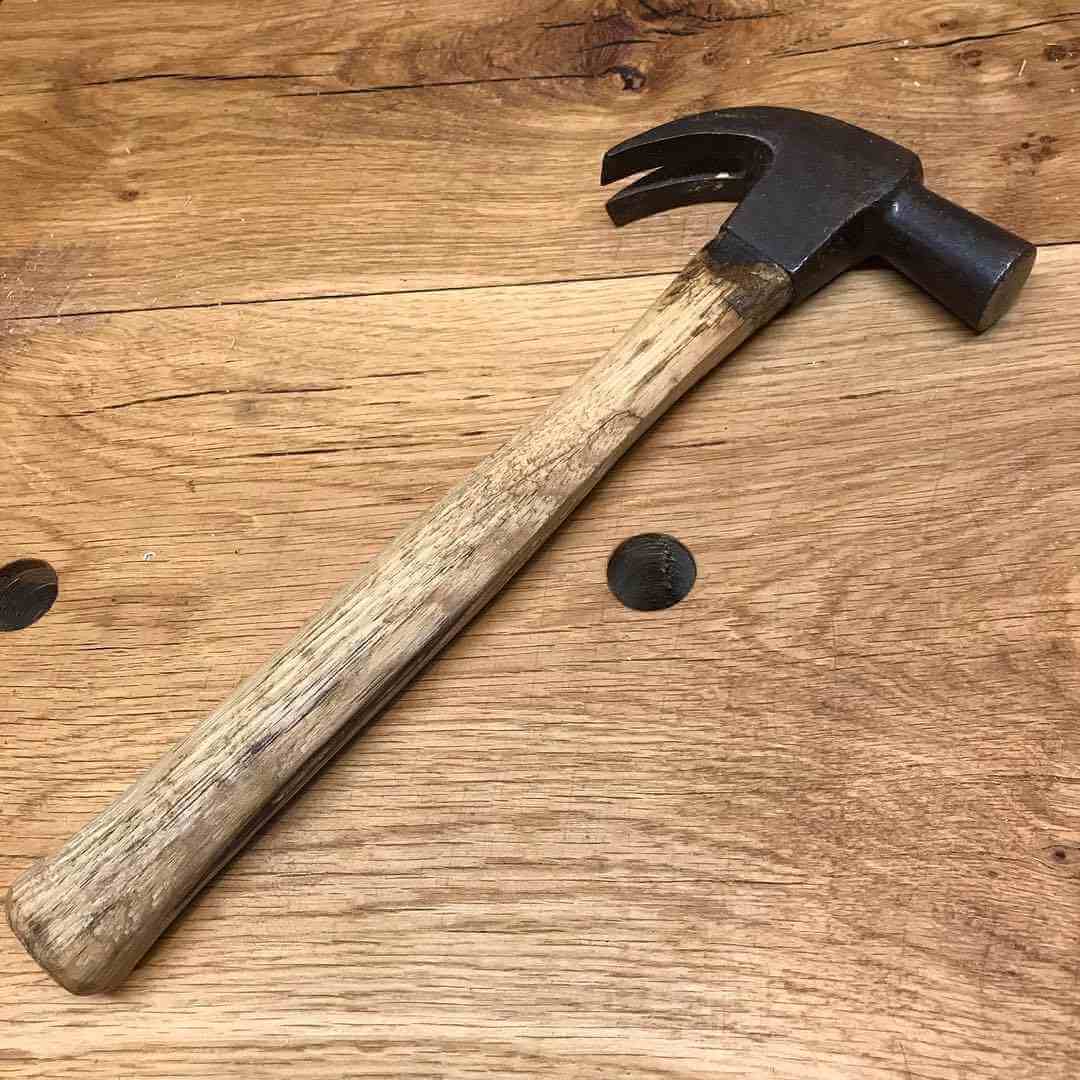

3 | Claw Hammer

If you currently own one hammer, it’s probably a claw hammer. Claw hammers are some of the most recognizable, versatile tools in the United States.

These basic hammers feature a flat, broad head on one side and a curved claw on the other. The claw functions as a nail grip—to remove a nail from scrap wood, just slide the claw under the nail head and rock the hammer upward.

You can find a broad selection of claw hammers in different sizes, shapes, and materials on the market today.

4 | Club Hammer

A club hammer (or lump hammer) has a unique shape compared to some of the other standard hammers on our list.

Club hammers feature a short, wide head with a flat surface on either side, resembling a sledgehammer.

These types of hammers are lightweight and suitable for moderate demolition work or for driving masonry nails.

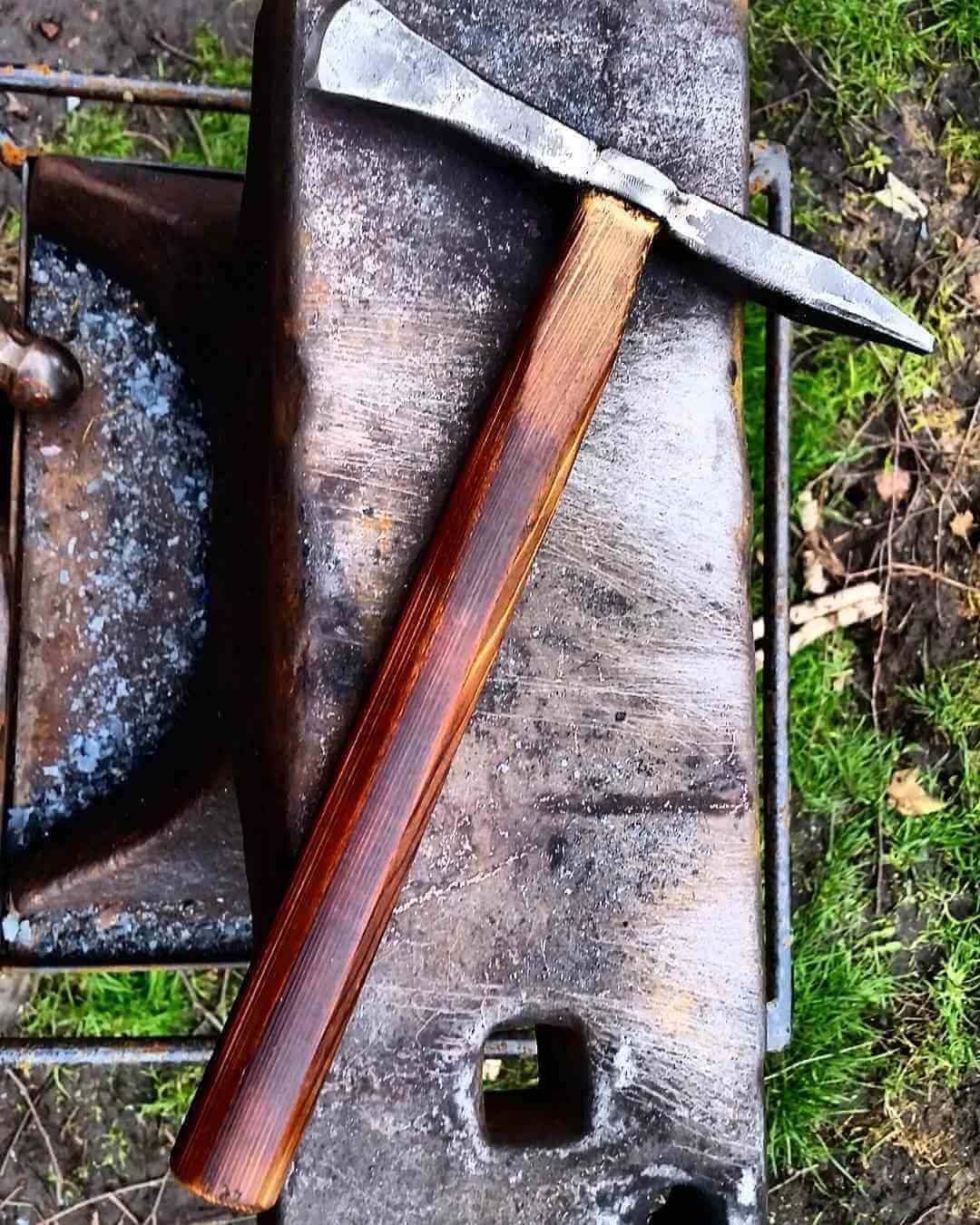

5 | Framing Hammer

A framing hammer is a popular style of claw hammer that features a straight claw and a waffled flat head.

Framing hammers weigh twice as much as traditional claw varieties, and this added weight allows them to strike and drive nails with little physical exertion from their handler.

Carpenters often use these tools to nail house frames. You can find several varieties of framing hammers at your local hardware store.

6 | Rubber Mallet

You may not think of a rubber mallet as a type of hammer, but it serves a similar purpose to standard hammers: delivering impact to a localized area.

Rubber mallets feature a bulky rubber head with a flat surface on each end, allowing them to deliver softer blows than a condensed metal hammer head could.

Masons often use rubber mallets to clear out large areas of concrete. The rubber mallet’s design allows it to deliver powerful force without damaging the material it strikes, making it suitable for sheet metal, wood, and upholstery projects.

7 | Sledge Hammer

A sledge hammer (or “sledgehammer”) has a long, sturdy handle and a wide, metal head.

These tools resemble a mallet, but their weight and density allow them to deliver more powerful, blunt force to the target area.

Many people use sledgehammers for demolition work or to drive stakes into the ground. If you’ve got heavy-duty DIY work to get done, a sledgehammer is a must-have.

8 | Straight-Peen Hammer

A straight-peen hammer is a blacksmithing hammer that features a circular, flat head and a narrow “peen” that extends out from the head.

Straight peen hammers are ideal for shaping metal in small, tight areas, as their flat heads give them exceptional precision.

Some workers also use small straight-peen models to start nails in wood, so they are a good hammer to have around the workshop for woodworking too.

9 | Tack Hammer

A tack hammer (also known as an upholstery hammer) features a relatively unique shape.

Tack hammers have two long, narrow faces, one of which is often magnetized and split down the middle to help hobbyists position tacks in upholstery.

The tack hammer’s overall body is small, allowing for precise, careful strikes. Upholstery hammers are also lightweight to ensure that they do not damage delicate fabrics.

10 | Trim Hammer

A trim hammer (or finish hammer) is a straight claw hammer that features a small head and a short handle.

The trim hammer’s design allows carpenters to drive tiny trim nails without damaging the surrounding wood trim or any other materials in their workshops.

They are the ideal hammer for those attempting to install baseboards trim jobs or even crown molding.

Specialized Hammers

Specialized hammers serve very particular purposes. If you only handle hammers for the occasional work or hobby project, you probably won’t have use for most of these specialty tools.

However, if you regularly work in industries like carpentry or masonry, adding a few of these hammer types to your collection could streamline your everyday work processes.

11 | Blocking Hammer

A blocking hammer is a type of blacksmithing hammer that features two distinct faces: one that is square and one that is cylindrical.

The blocking hammer’s overall head is dense and heavy, allowing blacksmiths to apply strong force to metal with little physical exertion.

Blacksmiths often use this type of hammer to shape or sink metal, as its heavy, flat faces allow them to create a smooth finish.

12 | Bushing Hammer

A bushing hammer is a masonry tool that allows stonemasons to add additional texture to stones.

The hammer’s rectangular head features four linear grooves on either side, and striking stone with this grooved surface creates a weathered-rock appearance on the stone’s exterior.

Stonemasons often use bush hammers to improve the aesthetic appeal of landscaping stones, increase the bonding ability for concrete slabs, or reduce the risk of slipping on stone walkways.

13 | Chipping Hammer

A chipping (or welding) hammer is one of the more peculiar hammer types on the market. If you spend any amount of time welding, you’re going to need a chipping hammer.

This tool features a sharp, angled chisel on one end with a pointy peen on the opposite end.

What makes the welding hammer distinctive is its spiral handle design that almost resembles a spring. This handle absorbs shock and deflects heat, minimizing the risk of injury while welding.

14 | Cross-Peen Hammer

A cross peen (or cross-“pein”) hammer features a wide, flat face on one side of the head and a wedged pein on the other.

What makes a cross pein hammer different from the straight-pein variety is the peen’s alignment. Cross peens align horizontally with the head of the hammer, creating a cross shape if you view them head-on. Alternatively, straight peens feature a vertical alignment.

The cross-peen pin hammer is a variation of the traditional cross-peen hammer that has a lighter body and a narrower metal face. This tool’s small, condensed head makes it ideal for cabinet work or other detailed woodworking projects.

15 | Drywall Hammer

A drywall hammer is a specialized tool that carpenters use to cut drywall. This hammer features a round, semi-flat head on one side and a hatchet-shaped head on the other side.

The hatchet end includes a rounded notch on the bottom that helps builders place nails in drywall.

Drywall hammers feature a smaller hatchet end than actual hatchet hammers, making them better suited for soft materials like drywall.

16 | Engineering Hammer

Engineers’ hammers—also known as ball pein hammers—feature two faces: one that is round and one that is flat.

This design helps engineers shape and harden metal materials to a degree. If you’re a HVAC tech or mechanical plumber installing ductwork, you’ll need one.

The ball pein hammer typically features a handle that absorbs shock and vibrations, allowing engineers to maintain precision and a firm grip while striking metal.

17 | Hatchet Hammer

A hatchet hammer looks more like a hatchet than it does a traditional hammer, and is similar in terms of looks to a roofing hammer.

These unique tools feature a small, rounded hammerhead with a flat and sharp hatchet end instead of a conventional type peen.

Survivalists and campers often include a hatchet hammer in their emergency supplies, as these versatile tools can help campers chop wood, build shelters, or fend off animals.

18 | Piton Hammer

A piton hammer is a specialized hand tool that rock climbers use to drive pitons into a climbing surface.

These hammer types include a straight, slim peen on one side and a flat, square head on the other. They often utilize a hollow hammer handle, making them lightweight and easy to transport.

Rock climbing enthusiasts may keep several kinds of piton hammers in their arsenal. You can find a wide selection of these tools on the market that vary in their head size, weight, and build.

19 | Planishing Hammer

A planishing hammer is a metalworking tool that blacksmiths use to restore metal or welded materials.

These hammer types feature a rounded metal head and a cylindrical peen. Metalworkers often use these tools to smooth any hammer marks they created when initially shaping the metal.

You can also find mechanical planishing tools that resemble large metalworking machinery. These mechanized tools roll, flatten, and polish the metal using numerous light blows, delivering more precise, localized force than humans can create.

20 | Power Hammer

A power hammer strays far away from the traditional image of a hammer. While several types of power hammers are on the market, the most common one is the nail gun, an electric hand tool that drives nails into wood joints and other surfaces with the press of a button.

Nail guns take most of the physical exertion out of driving nails into dense, rigid materials.

However, their powerful, mechanical force makes them unfit for precise tasks like metalwork or upholstery.

21 | Lath Hammer

Not to be confused with a “lathe” hammer, a lath hammer resembles a small-looking hatchet-type hammer used primarily for drywall jobs.

These tools include a square face on one side of the head and a short, flat hatchet on the other.

Carpenters often use these types of hammers to cut and nail laths for plaster. They are ideal for demolition works, and minor foundational altercation works.

22 | Scaling Hammer

A scaling hammer is a specialty tool that carpenters use to chip away paint, rust, corrosion, limescale, or other unwanted coats from wood or stone. You can find manual and powered scaling tools on the market.

Manual scaling tools resemble two-headed chisels, with one vertically aligned head and one horizontal one.

Meanwhile, powered scalers include three or four small heads that extend from a wide base. These heads vibrate and spin, breaking up the material below. After using a heavy-duty power scaler, workers can remove paint or remaining rust easily with a brush.

23 | Scutch Hammer

A scutch hammer features two wide, chisel-like faces that extend outwards from the handle.

A builder may use this hammer to cut bricks to specific lengths, as the tool’s sharp head delivers pointed, linear blows.

Some scutch hammers include toothed chisels rather than flat ones. These chisels resemble a comb and are better suited for breaking lighter, less dense bricks or blocks.

24 | Shingle Hammer

Also known as a roofing hammer, the shingle hammer is ideal for hammering nails and creating nail holes in roof shingles. This tool has a square face on one side of the head and a sharp spike on the other.

Roofers use the spike to create a hole in the shingle before hammering the nail into the material. Shingles are often soft and fragile, and attempting to drive a nail into the surface directly could fracture the shingle.

The spiked side of the hammer’s head often features a divot that helps roofers remove nails that they secured in the wrong spot.

25 | Sprig Hammer

Our last specialty hammer is the sprig (or picture framer’s) hammer. Framers often use these small tools to drive sprigs or brads into a picture frame.

Sprig hammers feature a square head and an angled shaft, allowing framers to nail a sprig into the frame while keeping their hands away from the target area.

In Conclusion

A hammer blow should carry enough force to move an object, such as a nail into a piece of wood, or to shape an object, such as the use of a round hammer to shape metal surfaces.

Key Takeaways:

Each of the hammer types we described features a unique handle, shaft, and head design that creates the proper force and precision for its specialized jobs, reducing the risk of injury and optimizing efficiency.