25 Different Types of Saws and Their Uses

Each type of saw you manhandle is designed for a specific application. From intricate woodworking and furniture making to robust construction and metalworking tasks. But which different types of saws do you really need?

In a Nutshell:

To master the art of craftsmanship, understanding the specific uses of various saws is crucial. A rip-filed hand saw excels in cutting along the wood grain, while a Japanese saw is ideal for precise, fine cuts in joinery. Use a dovetail pull saw for crafting dovetail joints, and a flush cut saw for trimming dowels and tenons. For tenon work in frame construction, a tenon back saw is your go-to. For broader applications, a circular saw makes quick straight cuts in sheet materials, and a jigsaw is perfect for intricate curved cuts in wood, metal, and plastic. Each saw has a unique role, enhancing precision and efficiency in specific woodworking tasks.

Whether crafting fine furniture to sell for your business or undertaking a DIY home renovation, the right saw simplifies the job and elevates the final outcome. So here are 25 different types of hand and power saws to consider for your tool collection.

25 Types of Hand Saws and Their Uses for beginner woodworkers

Hand saws, a staple in traditional carpentry, have been passed down through generations. These essential tools, including various types of hammers and saws, were used to craft everything from bed frames to cabins.

Known for their manual operation, hand saws may not be fast like power saws, but they hold a special place in craftsmanship. Ideal for beginners, hand saws offer ease of use and a sense of classic woodworking skill.

Different types of hand saws for woodworking

While the handsaw, hacksaw, and pruning saw are the three most common types of saws, you can find a wide variety of other options to suit your project’s requirements.

5 most common types of hand saws

| Type of Hand Saw | Primary Use/Application in Woodworking |

|---|---|

| Rip-filed Hand Saw | Ideal for cutting wood along the grain. |

| Japanese Hand Saw | Perfect for precise, clean cuts in joinery and fine woodworking. |

| Dovetail Pull Saw | Used for making dovetail joints in cabinetry and fine furniture. |

| Flush Cut Saw | Designed for trimming dowels and tenons flush with a surface. |

| Tenon Back Saw | Best for cutting tenons in frame construction and detailed work. |

Keep in mind: These saws are rather common for expert woodworkers but not considered essential. But what are some must-have hand saws necessary for woodworking success? Scroll a little further to find out.

1 | Japanese Saw

The nokogiri is a type of saw that’s useful in Japanese carpentry. While Europen saws cut on the push stroke, the Japanese saws cut on the pull stroke instead.

The European method of cutting on the push stroke permits you to throw your body weight into the cut.

However, the Japanese saw proves to be more efficient than its European counterparts when making narrow and exact cuts.

The type of blade inside a Japanese saw is flexible and thin for greater accuracy. The teeth are so fine that you would ruin the blade if you were to cut through metal with it.

2 | Miter Box Saw

Also known as tenon saws or back saws, due to the strip of steel that runs along the back of the blades, miter saws can make extremely fine and ramrod-straight miter cuts.

High-performing miter saws should have about 80 teeth per inch on their blades. The correct number of teeth per inch results in a clean cut of your materials. Due to their short size and design, back saws are reliable for creating consistent cuts at an angle.

With a primary use for cutting wood joints, the miter saw utilizes clamps, known as miter boxes, for extra reinforcement around its blade. Stabilizing boxes are user-friendly and essential when completing molding work.

3 | Bow Saw

The bow saw would feel right at home in the weathered hands of a first-generation American settler, cutting wood and logs to build a homestead that can withstand winter’s oncoming snowstorms.

Also known as crosscut saws, the design and purpose of bow saws is to cut rough wooden surfaces. The crosscut saw features a thick blade with large saw teeth.

Another option for getting your work done faster is investing in a two-person crosscut saw. A traditional two-person crosscut saw has a handle on each end and demands collaborative work since each person must push and pull the blade when cutting wood.

4 | Coping Saw

A favorite of furniture makers due to its narrow blade, the coping saw cuts through most material and is ideal for detail work.

Intricate cuts become simple with coping saws since they can cut through a hole or carve through a cutout.

To use your coping saw, remove the blade, string it through the hole, and then begin cutting. If you’re crafting baseboard for a trim job, this saw is a must.

5 | Fret Saw

Like the coping saw, the fret saw also uses a thin blade, making it an ideal type of tool for complicated cuts.

The fret saw’s sizeable frame can cut farther from the outer edges of your task.

The only downside to the fret saw blade is that it cannot turn, making it less useful when cutting narrow components.

6 | Hack Saw

With its fine-toothed blade, the hack saw is one of the better tools for cutting metals like aluminum, brass, steel, or copper pipe and or tubing.

Due to its C-shaped frame, this type of blade stays secure when it lances through your material.

Many experts consider hack saws to be the best saw for beginners. These saws are versatile and strong, allowing you to cut through wood, metals, and plastics with ease

7 | Keyhole Saw

If the interior of your wall prohibits the use of power tools, pick up a keyhole saw at your nearest home improvement store.

The keyhole saw has a round handle with a single blade that efficiently cuts patterns and circles.

These saws are useful for cutting and puncturing through panels and drywall with the forked edges of their blades. Even if you have access to power tools, this type of saw is a great helpmate since it creates the initial hole for easier access.

8 | Pruning Saw

We are willing to bet that the landscaping truck driving ahead of your car might have a pruning saw in its flatbed.

Landscapers use pruning saws in their outdoor gardening due to the saws’ effective blades.

A pruning saw’s blade can be useful for cutting in both directions, and it successfully removes material, such as branches and thick vines, at a quick speed.

The pruning saw also boasts more teeth per inch on its blade than other saws in its size category.

9 | Rip-Cut Saw

Conversely, rip-cut saws have relatively fewer teeth per inch than other types of saws.

However, the rip-cut saw makes up the difference by having each tooth optimally sharpened for wood removal. The rip-cut saw comes in varying lengths and can be useful in cutting wood and in framing.

Rip-cuts sever lumber parallel to the grain by lifting up small splinters of wood, essentially chiseling the wood away. Many expert carpenters consider rip-cut saws to be the best saws for cutting wood, though several others on our list will get the job done as well.

10 | Hole Saw

Unlike other saws with their multiple uses, the hole saw’s sole purpose is to cut perfectly round holes in your material.

Hole saws attach to your drill and feature interchangeable blades, depending on your materials’ thickness.

The hole saw’s diamond-coated teeth can cut through plasterboard, hardwood, stainless steel, and concrete.

Types of Power Saws Used for Woodworking and Construction

Power saws are a testament to progress and our never-ending quest for ease. As the evolutionary step up from hand saws, power saws claim the title as the most commonly used sawing tools.

Top 5 Power Saws for Beginner Woodworkers

| Type of Power Saw | Primary Use/Application in Woodworking and Construction |

|---|---|

| Circular Saw | Versatile for making quick straight cuts in wood, metal, and plastic; ideal for framing and sheet materials. |

| Miter Saw | Precision cutting for angles and trims, perfect for molding and framing tasks. |

| Table Saw | Best for long, straight cuts; essential for ripping boards and sheet materials. |

| Jigsaw | Ideal for intricate cuts and curves in wood, metal, and other materials. |

| Reciprocating Saw | Excellent for demolition work, cutting through wood, metal, and plastic, particularly in tight spaces. |

Note: If you’re new to woodworking or you’re an apprentice starting in the construction industry, you don’t need to purchase all of these tools at once. Buy what you need, as all of these power tools aren’t essential.

11 | Stationary Band Saw

Band saws cut swiftly through wood, pipes, and tubes with their long, interchangeable blades.

While its varying saw teeth allow for precise cuts and the creation of numerous shapes, the band saw’s limitations include a lower cutting depth and frequently leftover rough sections. Once installed, you will find this type of band saw unable to move.

To use the band saw, manually feed your material into the blade. As the blade descends, the saw will cut through the wood.

You can choose many different types of saws, including the benchtop saw, the horizontal saw, the vertical saw, the meat saw, and wood band saws.

12 | Portable Band Saw

Say yes to giving your neighbor a helping hand by carrying over the portable band saw. The portable band saw is also perfect for lugging to a job site as it is not too heavy or cumbersome.

This type of saw may take more work to achieve straight cuts, but its fine teeth still make the portable band saw a viable choice for any cutting task you might undertake.

13 | Circular Saw

While using your head to cut through a concrete block is impressive, you can achieve the same results with a less-risky circular saw. Popular in building projects, circular saws are lightweight and portable.

Different types of saws include the corded circular saw, the worm drive circular saw, the sidewinder circular saw, the hypoid circular saw, compact and mini circular saws, and track saws.

The circular saw requires manual operation since you must push the saw’s round blade through the cutting material. The electric motor spins the blade as the circular saw passes through the material, achieving curved cuts and straight-line sections.

14 | Compound Miter Saw

The miter saw and the compound miter saw can both cut at an angle and are excellent for framing.

However, the compound miter saw’s blade is superior for complex angles since it mounts on an arm that can adjust and tilt.

This type of saw is generally useful for homebuilders when trimming out windows or adding crown molding.

15 | Panel Saw

Did you ever go for a walk around town and see giant storefront signs spelling out services such as “Ice cream treats” and “TVs at unbeatable prices”? These advertising signs are typically the creations of a panel saw.

As the name suggests, the saw cuts through large panels such as aluminum composite, wood, particleboard, ceramic, plastic, laminate, and sandwich panels.

Two different saw types are available: the vertical saw and the horizontal saw.

The vertical saw, or standing saw, can be either automated or manually operated. These saws are also space savers as they mount onto walls. The newest models of these saws are technologically advanced, empowering you to control them via touchscreen.

The horizontal saw uses a sliding feed table and requires a large footprint. This type of saw holds your material steady while you swing the teeth of your blade through it.

These saws come in many different sizes for home and commercial projects. Large-scale models slice vast wood panels in timber yards.

16 | Radial Arm Saw

The radial arm saw design is similar to the miter saw, with both saws utilizing circular blades to execute crosscuts, miters, and bevels.

However, the radial arm saw has some notable distinctions.

The motor and the cutting blade of this saw are on the arm, giving it a higher cutting depth. Having the arm positioned over the saw table allows the blade to pierce through the thick wood.

The radial arm saw can also create a greater variety of cuts, including identical compound cuts and angled cuts, while the limits of miter saw are typically less than four cuts.

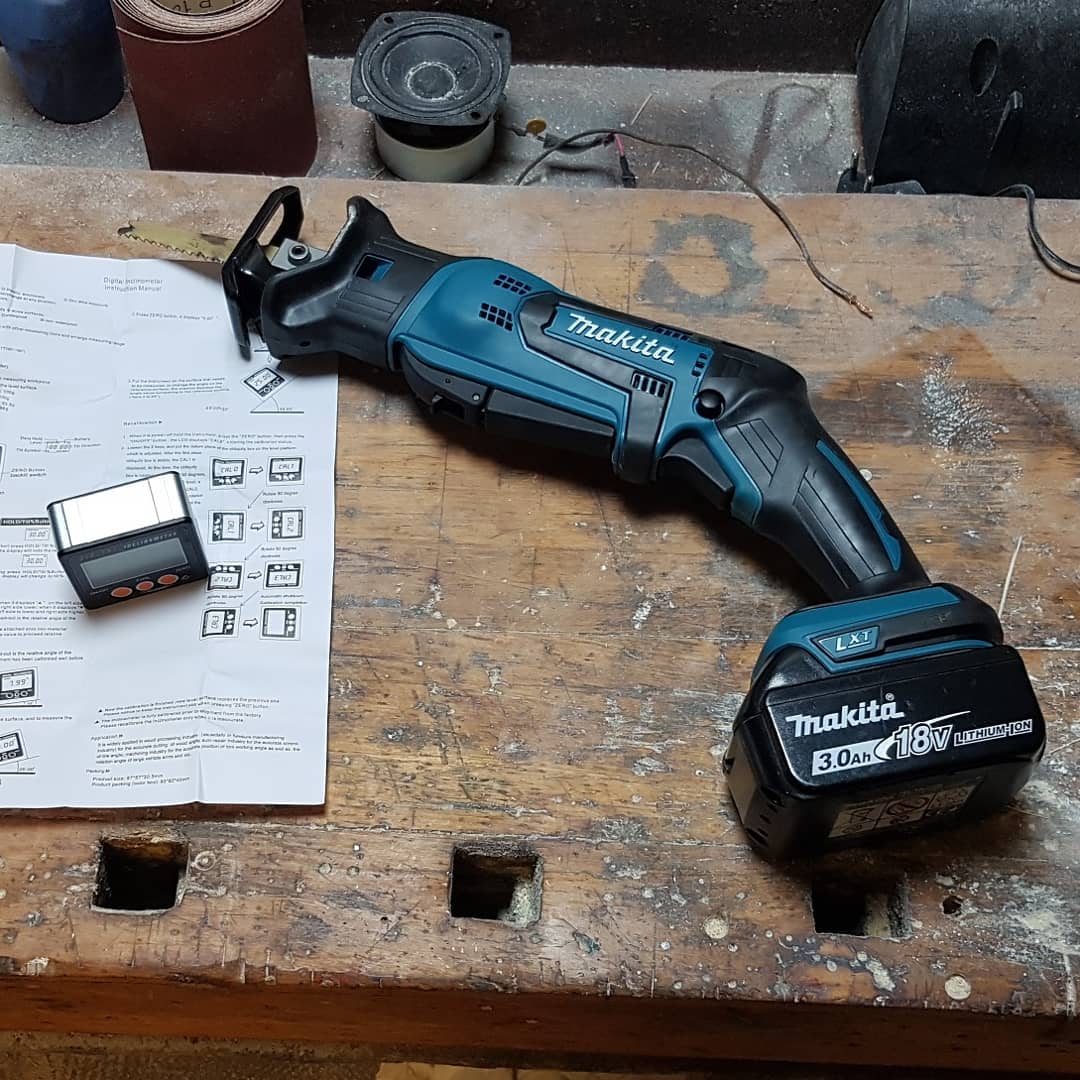

17 | Reciprocating Saw

Reciprocating saws have a reciprocating blade that rapidly moves back and forth, cutting through plastics, wood, metals, and even nails.

A favorite tool for demolition work, the reciprocating saw can dismantle drywall and battens, and cut beneath wood joints with relative ease.

Reciprocating saws require minimal physical effort and can rip through the toughest of materials with a decent blade attached, and as a contractor, you really do need one.

18 | Scroll Saw

Featuring a narrow blade that easily slices your chosen patterns, the scroll saw is a type of table saw specializing in finely detailed work.

Use the scroll saw to produce intricate scrollwork, create curves with edges, and saw complex shapes in thin material. These saws come with work tables that swivel for your convenience.

Additionally, any residual sawdust from working with these saws gets blown away by a small plastic tube. This feature grants you an unobscured view of your cut line.

19 | Table Saw

Table saws come complete with high-speed motors mounted beneath their flat tables. If you need to adjust your cut’s depth, the blades will rise up and out of your table bed accordingly.

Whether you own metal or masonry blades, the table saw will accept them as long as the blade design is congruent with the motor rpm.

For safety’s sake, be sure to check your table saw’s specifications before operating, and regular maintenance can not be ignored with table saws.

20 | Track Saw

The track saw functions in a similar way to a table saw and circular saw, with its appearance favoring the latter.

Ripping straight lines with accuracy is the department where these saws excel. To use the track saw, line up the track on your cutting mark and place the saw on its rails.

The saw glides as smoothly as scissors do through wrapping paper, making a perfect cut with minimal effort on your part.

21 | Chain Saw

A biting freeze is in the air as you and your friends tip-toe through the winding corn maze and into the haunted house. The darkness and silent gloom of the rickety shack are all-consuming until you hear an even more frightening and visceral sound that makes you flinch.

It is the sound of a chain saw revving up directly over your shoulder.

When not engaged in terrifying tourists during October festivities, chain saws have their primary use in woodworking.

A chain saw’s gasoline engine can last for up to 10 hours without overheating, making them more suitable for outdoor work than other types of electric saws.

Chain saws are also weather-resistant, so some scattered rain clouds will not derail your project’s timeline.

22 | Pole Saw

A pole saw can lengthen your reach when trimming dangling tree limbs in preparation for a hurricane or cutting away some kudzu to create unblocked sunshine.

The pole saw has many uses, including transforming into a chain saw if you remove the shaft and its handles.

Types of pole saws include the electric pole saw, the gas pole saw, the manual pole saw, and the cordless pole saw.

23 | Jigsaw

Trust us, do not watch the horror movie “Jigsaw” if you are trying to learn more about how jigsaws work and why they might be the best choice for you.

Instead, let our professionals at The Tool Scout tell you all about it! You’ll find no games here – just a powerful saw capable of beveling up to 45 degrees.

The jigsaw incorporates an electric motor that powers up the blade and cuts through materials such as carpet, ceramic tile, countertops, and metal. It is a handheld device that cuts flawless curves.

24 | Flooring Saw

Are you upgrading your home from dated carpeting to timeless wood flooring? A flooring saw is a portable tool that can make your workstation mobile.

You will no longer need to chain yourself inside your garage, only to emerge when hefting heavy wooden planks up your staircase.

Instead, use the transportable flooring saw to cut hardwood, laminate, or bamboo pieces for your specific dimensions.

25 | Oscillating Saw

The oscillating saw’s body is reminiscent of a grinder, but with one glaring addition: a swappable oscillating attachment at the end.

Oscillating saws are very underrated and have many uses, such as cutting materials, grinding, scraping, and removing grout or caulk.

In my early years as an apprentice cabinetmaker, this was a tool that I’d use on a daily bases for fine crafting table legs and niche shelving.

In Conclusion

While you might not need many of the saws mentioned for basic DIY jobs, as you advance these types of tools will become a necessity.

Key Takeaways:

Whether you need a delicate tool for fine joinery or a robust tool to cut metal, selecting the appropriate saw is key to achieving precision and efficiency in your projects.