Can an Angle Grinder Cut Metal or Steel?

There is one question that is quite common on the relevant boards, and that is: “Can an angle grinder cut metal?” The short and simple answer? Absolutely!

In fact, in the sea of hand-held cutting tools for metals, the angle grinder seems to be the most versatile of the bunch for metalwork.

But should you add an angle grinder to your tool collection if you’re regularly cutting metal or keep things simple and cheap with a trusty hacksaw?

Can an Angle Grinder Cut Through Metal?

The best angle grinders are made to cut through harder metals, as well as bricks and or concrete, so you’ll have no concerns when it comes to durability. A good grinder will become a necessity and not a luxury when working with metals or even steel.

Now while you’re average DIYer typically won’t be hacking into dense steel on a daily basis, a quality grinder is certainly the one tool you’ll want in the back of your truck or workshop when endeavoring to make quick cuts into metal materials.

The time it takes an angle grinder to cut through a section of threaded rod in comparison to a hacksaw is startling. Simply put, angle grinders are a HUGE time saver when it comes to cutting metal.

That’s why it comes as no surprise as this particular tool is consistently used by a whole host of different trades, including those folks in the automotive industry, HVAC, plumbing, and many others.

Grinders are primarily utilized for refurbishing and polishing metal materials, so it shouldn’t surprise you that as long as you have the right disc equipped, you can have at it with even stainless steel surfaces.

Note, you shouldn’t go into the process without any precautions. While angle grinders are great for hacking at aluminum or metal stock, there are some safety considerations for beginners to think about.

What Can Be Used to Cut Metal?

Well, if you’re still stuck in the 20th century where power tools like angle grinders aren’t yet the tool of choice, you could leisurely stroll over to the nearest tool shop in your horse and cart and begrudgingly reach for what is known as a “hacksaw”.

Hacksaws can be used for simple DIY tasks like cutting metal stock, and with enough brawn, you should be able to power through something a bit thicker with enough huffing and puffing.

Now, if that doesn’t sound like your glass of Jack Daniels, you could always join the rest of society in the 21st century and make use of an angle grinder for all your future metalworking jobs.

All jokes aside, as long as you’re using the right grinding disc or cutting wheel for your specific grinder (model), cutting and grinding metal materials will be an absolute breeze.

So here’s my compelling case for why you should use an angle grinder for cutting metal like; rebar, angle iron, sheet metal, and just about anything else.

The Mechanism of an Angle Grinder

As we mentioned above, the angle grinder is one of the most popular products on the relevant market. There are a number of different variations of angle grinders; they come in different sizes and with or without a cord.

Personally, going with a grinder of the cordless variety is by far the better alternative in our opinion. Power tools of the cordless variation provide more than adequate power and much greater versatility.

But, whether you use a corded angle grinder or cordless grinder is really irrelevant as either will cut through metal. What you do want to ponder is the size and cutting capacity of the grinder. The most common angle grinder adopted seems to be the 4-1/2 inch model.

If you go with a corded grinder, you should expect a motor with a power capacity of around 9 amps; this will be more than enough to deal with most hard materials.

Although if you’re going the cordless route, don’t go for anything less than an angle grinder utilizing a brushless motor with a 20V Lithium-Ion battery. Cordless grinders are mostly all 4-1/2 inches in terms of capacity and can handle anything from mild metal or steel fabrication, concrete restoration, and or copper pipework.

Apart from all that, a good angle grinder comprises a spinner washer, a comfortable handle, and a protective blade or disc cover. I know, all that sounds nice, but how exactly can you use angle grinders to cut metal? Well, maybe because it can achieve up to 15,000 rotations per minute.

That’s honestly a hell of a lot of force generated by a hand-held power tool. But is it enough to constructively cut cast iron pipe with an angle grinder, and or thick metal/steel? Let’s find out.

How to Cut Metal With an Angle Grinder

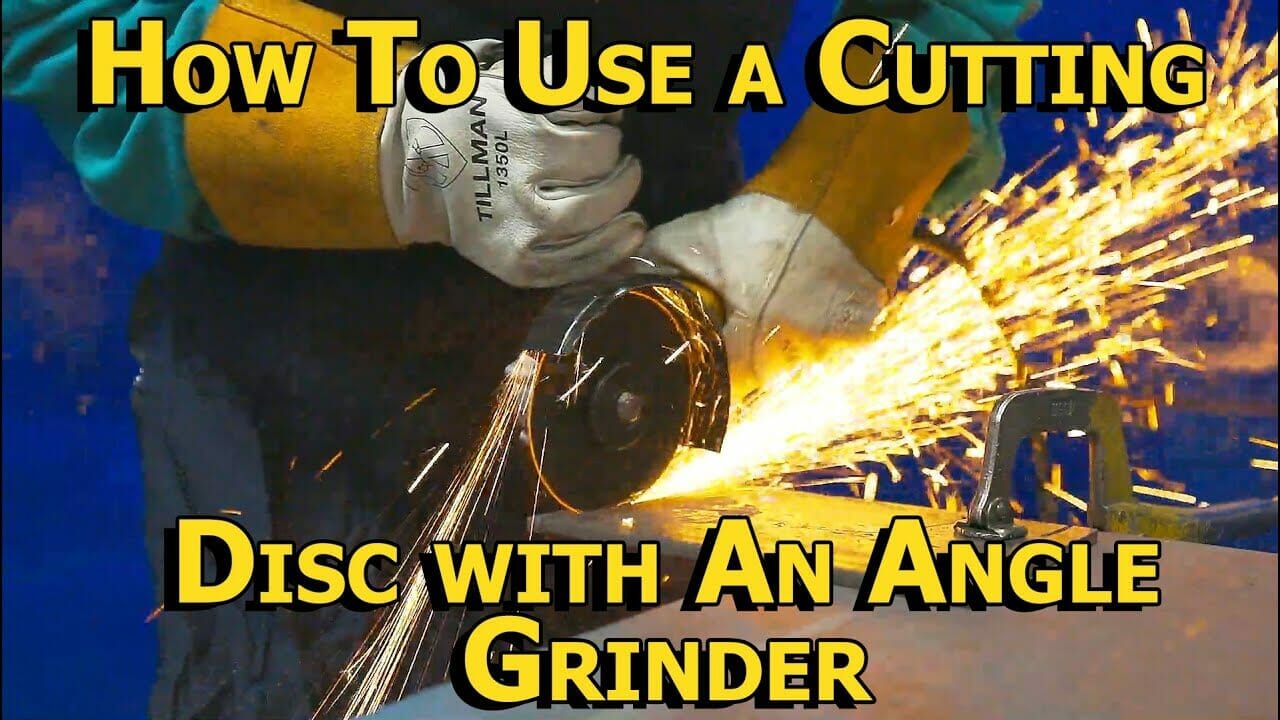

Now that we’ve established the concept of an angle grinder for metalwork, it’s time to move on and see what exactly is the best method for chopping metal with a grinder.

We have to suggest that the process is not always the same, as various angle grinder models function differently.

Still, the precautions that you need to take are pretty similar when attempting to cut metal or steel.

Cutting Metal With Angle Grinder – Step-By-Step

- First and foremost, you should ensure that you have all the required tools for this process. Apart from the angle grinder, this includes a power source and a long cable (unless it is the cordless model), along with the earmuffs, safety goggles, C-clamp, and an adequate metal cutoff disc. Last but not least, you should have the metal that you want to cut, set, and ready.

- Once you have all the tools set and ready in place, it is time to prepare the angle grinder for the cutting process. That is done by attaching the appropriate metal cutoff disc and putting the spindle nut in the right place. Also, unless the angle grinder that you are using is cordless, this is the time to plug it into a power source.

- The next step is to fix the metal and mark the cut with a permanent marker. Once you have done that it is time to begin the process. Hold the angle grinder with both of your hands and start cutting with firm precision. Follow the line that you have previously marked and control the kickback ensuring that the cutting is light and smooth.

Note, if there is a need to change the direction, you should do so very carefully without any intense or sudden moves.

This way, you will protect yourself from injury and ensure that the cut remains precise. Once you are done, check for any rough edges and use a flipper to correct these.

What we personally recommend is to finish any cut you commence in its entirety. Doing it halfway and leaving it for another run can only increase the chance of an imprecise and ugly-looking cut.

When you’re tackling thicker metal or steel materials with a grinder, patience is a virtue that you, unfortunately, might have to possess.

Can an Angle Grinder Cut Steel?

It really depends on both the cutting capacity of the angle grinder and the size/type of disc you’re using. Apart from all that, the thickness of the material you’ll be cutting is a determining factor for estimating the potential cutting depth of the steel.

Not only that, cutting discs are available in different thicknesses, and you’ll need to select the right size disc.

But let’s assume you’re using a 4-1/2 inch grinder (like most people) with a flat diamond cutoff blade for cutting either stainless or mild steel. For cutting the stainless steel, you should use a 1mm or 1.6mm iron-free disc.

If you’re cutting thin metal materials like sheet metal, it would be best to use a 1.0mm or 0.8mm cutting disc. Either of these discs will exhibit a cleaner-looking cut and minimize any potential discoloration due to the reduction in blade thickness which will result in less heat transfer.

When using an angle grinder to cut or buff metal or aluminum, utilizing a type of saw lubricant will help preserve the lifespan of the disc and eliminate the possibility of chipping.

How Thick of Steel Can an Angle Grinder Cut?

Now, if you’re going to be chopping thicker, heavier steel such as rebar or structural steel like angle iron, you’ll require a cutting disc between 1.6mm or 2.5mm in thickness. Making use of a thicker blade like a 2.5mm cutting disc for chopping through dense steel does have some drawbacks.

In some cases, the finished cut of your steel workpiece can exhibit signs of discoloration due to the reduced blade speed with the larger disc-equipped. Why is that? Essentially, because of the increase in friction.

So depending on how dense the material is and how clean or cut you’re expecting, you could always consider another power tool for cutting metal.

Either a metal cutting circular saw, or a metal chop saw are two of the usual suspects that pop to mind when precision and finesse are considered a priority when cutting thick, dense steel.

But, if you’re only interest is to make quick cuts where precision and overall appearance are an afterthought, by all means, break out the trusty grinder. Just make sure to use the recommended discs when need be.

In Conclusion

So can an angle grinder cut metal or even dense steel? Yes, it most definitely can. At the end of the day, using an angle grinder to cut metal can be highly effective and extremely safe as long as you have the right equipment and safety tools with you.

If you’ve never operated a grinder before, you’ll need little practice to master the art of effectively slicing and dicing said materials. That is, as long as you’re operating this powerful hand-held tool with the correct cutting disc.

Lastly, make sure that you are safe with full control when wielding a grinder, and always wear the correct protective safety glasses when operating the tool. So all that is left now is to choose the right cutting disc and your material of choice and get cutting metal with ease.