Can You Buff & Polish Any Metal Surface With an Angle Grinder?

Can you buff with an angle grinder? Well, if you’re considering using a high-speed angle grinder to buff and polish your beloved 77′ Ford Pinto to socially acceptable levels where the opposite sex doesn’t cackle like a gang hyenas as you roll by, go ahead, have at it.

Why is that you wonder? Well, let’s just say, no one is really going to notice the difference when your regular grinder takes three layers of paint off of that Pinto.

This is because different angle grinders operate at various speeds in terms of their RPM output.

That said, what if you do have an angle grinder that produces lower operating speeds or even a grinder that has a variable speed control feature? Well, that (kinda) changes everything, as you likely be able to utilize such a grinder on some more delicate surfaces that you were contemplating buffing or polishing.

Nonetheless, let’s get started with the exact steps for you to successfully utilize an angle grinder to buff and polish just about any inanimate object.

Can You Use a Grinder to Polish a Car?

One of the most likely reasons you’ll want to transform your angle grinder into an electric buffing and polishing machine is to bedazzle the bejesus out of your prestigious whip.

Buffing any car can be done via Manuel means by simply using your hand, but then again, it’s not 1954, and you’ve probably got more exciting things to do with your hand thanks to the internet.

One of the very few angle grinders you could use for buffing and polishing your precious hoopty is the Bosch GWS13-50VSP.

Why’s that? Because angle grinders like the GWS13-50VSP feature a variable-speed setting which allows you to adjust the grinder’s motor speed from 2,800 rpm to 11,500 RPM.

Fitting a 4-inch buffing and polishing wheel to this type of grinder would pose you no problems as dedicated buffing and polishing tools that professionals use, operate within the same speed range.

What you will need to get your buff n’ grind on is a polishing and buffing kit that utilizes an M10 adaptor which is suitable for angle grinders with a 5/8-inch arbor.

Now keep in mind, that if you go with the larger surface area buffing pad, you’ll have to remove the wheel guard to enable you to use the larger type pad.

What if You Don’t Own a Variable Speed Angle Grinder?

Your typical angle grinder (that most people own) generates around 8000+ RPM and operates only at a fixed single speed.

While all those revolutions per minute are fantastic for hacking lengths of angle iron into pieces, such speed with a buffing and polishing wheel attached is only going to reduce your fancy-ass paintwork back to bare metal.

Now if the angle grinder you currently own doesn’t utilize this essential variable speed feature and you’re not too keen on upgrading to a model like the GWS13-50VSP, I recommend you consider other options. Like what you ask?

Going with a dedicated buffer and polisher tool that has been specifically engineered to remove swirls, scratches, and defects explicitly for painted vehicles. As this is a tool that has a specified use case, it is rather limited.

Although, if you enjoy working on your car and are content spending your spare time polishing your ride regularly, the price of owning such a specific tool can be easily justified.

Using Cordless Drill as Polisher

Another cost-effective viable option is to use your cordless drill by utilizing one of the many attachments particularly designed for buffing and polishing.

Cordless drills are an ideal alternative as they possess selective speed ranges averaging between 500 to 2000 RPM with the flick of a switch, which is beneficial for buffing and polishing paint.

In short, there’s a multitude of ways to buff and polish your pride and joy while pounding beers in the sun blasting Guns N’ Roses, just make sure you use the right tool.

How to Polish Metal With an Angle Grinder

There are a number of alternatives when using an angle grinder to polish metal materials, and the application will also determine the necessary progressive steps you should take. But let’s start with the basics.

Here’s everything you’ll need to constructively polish metal or even stainless steel with an angle grinder:

Getting Started

Alright, let’s assume that the metal material you’re interested in sprucing up has about as much mileage on it as Aerosmith’s Steven Tyler. Thankfully, to rectify this situation, you won’t have to endure 6-months of rehab at Club Med with a team of psychiatrists working around the clock to make things right again.

Instead, you can simply get things moving in the right direction by simply attaching a Scotch-Brite or Easy Strip disc to your angle grinder to eradicate any rust, paint, scaling, and oxidation.

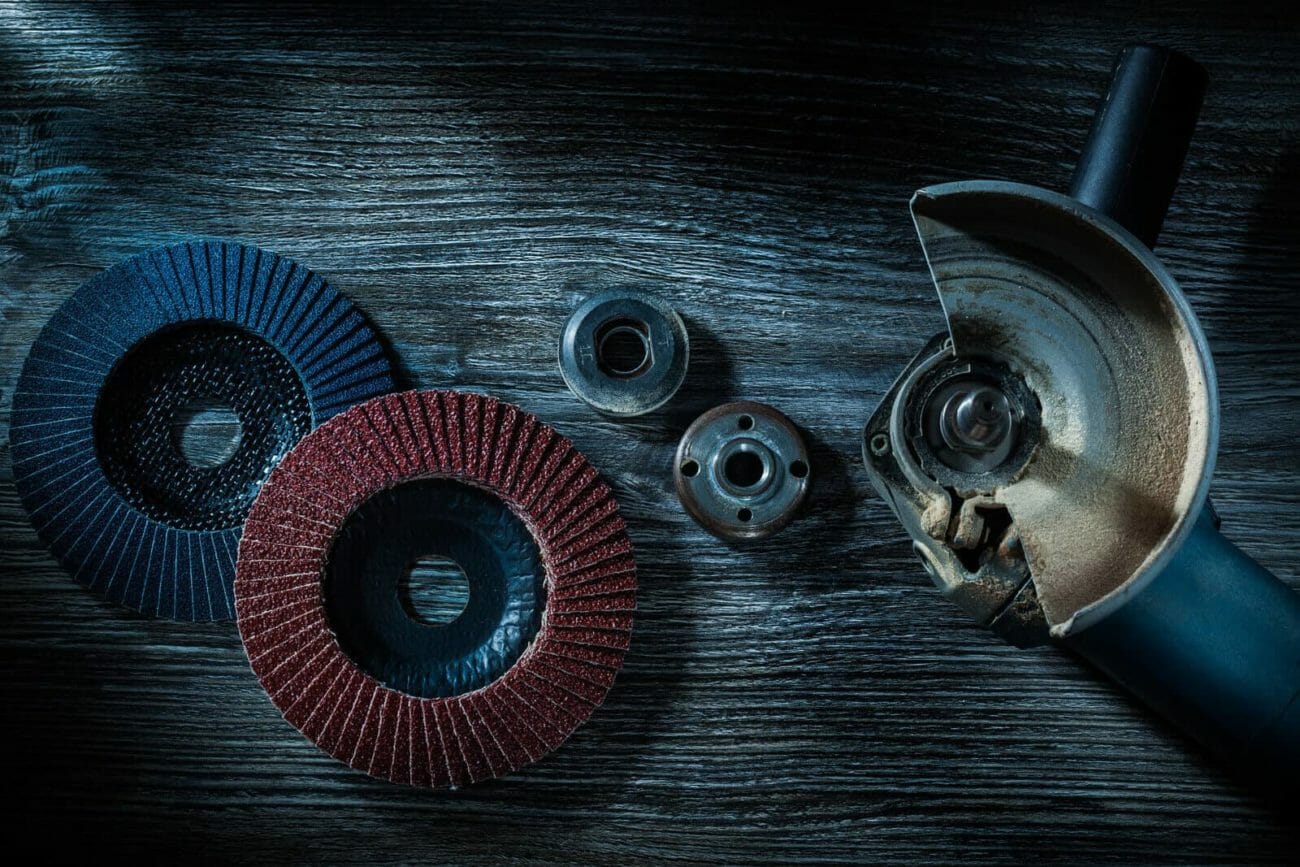

The most popular method for making metal surfaces like new again involves getting your mitts on an abrasive flap disc for your angle grinder. Such a disc allows you to constructively polish metal or even stainless steel and is ideal for those who are just looking to remove rough edges and unsightly metal burrs.

These abrasive flap discs are made from zirconia abrasive ribbon and are a brilliant cost-effective option that the majority of metalworkers and DIYers use.

Depending on the condition of your metal or stainless steel material and what you plan on using it for, you could just opt for the finer finishing disc. Felt polishing flap discs are typically used in the final stages of polishing and when utilizes correctly, they provide a fantastic high gloss mirror finish.

The only downside to felt discs is that they’re not the best bang for your buck as they’re made from wood material. When it comes to cutting and grinding with wood related materials, there are some obvious durability concerns.

So, let’s cover the exact steps necessary for you to productively polish the Christmas stuffing out of any metal material.

Once done, you’ll be able to proudly spend the rest of the afternoon admiring your own reflection in the freshly polished surface you just vigorously accosted with your angle grinder.

Step-By-Step Process for Polishing Metal

You’ll need to conduct the following process for a perfect reflective finish:

- Fit a Scotch-Brite or Easy Strip disc to your angle grinder and start by removing any rust, scaling or paint if need be.

- Next, utilize an abrasive flap disc to abolish any irregular rough edges and metal burrs. This technique will adequately polish metal and stainless steel to relatively decent levels (most DIYers will stop here).

- Once you’ve polished away the uneven jagged edges, apply a sufficient amount of polishing compound to the surface area.

- Now replace the abrasive flap disc with a felt polishing disc and continue to polish any obscurities until you get the crystal clear finish you want

The last two things you’ll require to effectively polish any metal surface to an almighty new level of shiny are simply time and patience.

Note, to get rid of any nasty saw marks for a mirror-like finish, you’ll have to repeat the above process to get the flawless-looking results you want.

What is the Difference Between a Buffer and a Grinder?

There are a few different types of buffers and grinders available and while you can go with bench buffers and grinders or handheld ones, the fundamental operating principles remain the same.

One of the main underlying differences between a buffer and a grinder is speed. A buffer operates at lower RPM than a grinder because you are endeavoring to refine and smooth the workpiece, not obliterate it.

The extra RPM grinders generate is imperative when attempting to cut metal materials, but it also creates immense friction. This friction is something you’d want to reduce when buffing.

Buffer vs Angle Grinder

The major dissimilarity between a buffer and grinder is the shaft size either tool employs. Your average run-of-the-mill angle grinder is equipped with a 5/8-inch diameter spindle (arbor) and has 11 threads per inch.

If you are interested in modifying your angle grinder for buffing and polishing purposes, you could always fit a spindle extender which will give you an extra 2-inches to work with… and no one ever complained about having an extra 2-inches to work with.

Lastly is the wheel guard that your classic angle grinder possesses for essential safety reasons. While you should never operate an angle grinder without a wheel guard, you’ll have to remove it when attempting to buff and polish as you need the additional clearance.

Can You Use an Angle Grinder as a Sander?

The short answer you’re looking for is, yes. You most certainly can use an angle grinder as a sander, and there are plenty of attachments on the market that will help you pimp your grinder to do so.

One prevalent shortcut that most folks opt for is to make use of a standard hook and loop sanding pad. This type of sanding pad can be easily fitted to any angle grinder with a 5/8-11 spindle.

Now, even if your small angle grinder is equipped with a smaller size spindle/shaft, you’ll be able to find an adapter to step down.

All that said, a standard angle grinder with a sandpaper pad just doesn’t stack up when compared to a palm sander that has been specifically engineered for one purpose… sanding.

Angle Grinder vs Sander

A regular palm sander is a tool that boasts a level of precision that most angle grinders severely lack.

Angle grinders, on the other hand, are more like a bull in the China shop that decided to throw an uncontrollable shitfit and bulldoze everything in its path at a moment’s notice. Why’s that? Because that’s what they are made for.

To slice, decide, and demolish durable-ass materials that otherwise should not be. They are the rough and ready power tool that makes light work out of heavy-duty work.

Ideally, at some stage, you’ll want to allocate a space in your workshop for both tools. Once you do start taking on multiple projects that require more time to complete, having both an angle grinder and sander on hand with greatly increase your productivity.

While there is obviously an abundance of tasks that can be conducted successfully with both grinders and sanders, overall, they are very different power tools.

In Conclusion

So there you have it. Hopefully, you’re somewhat wiser about all things related to buffing, polishing, and sanding.

Just think, you could have spent the past 11 minutes meticulously researching explicit scenes from around the web while pumping up Kleenex’s share price in the process. Alternatively, you now possess the cognitive ability and expertise to create a whole horde of shiny new objects with your very best angle grinder. Good for you.

Lastly, if you’re a complete beginner, I’d recommend you get ahold of some standard-type flap discs and try your luck out with some rudimentary buffing and polishing jobs. The good news is that flap discs (and even felt flap discs) are quite reasonably priced.

While they are considered a consumable item, if you buy them in packs of ten or more, you’ll assuredly use them around the house for future DIY projects.